Greater Nanaimo Water Pollution Control Center Expansion & Upgrades

The Greater Nanaimo Wastewater Treatment Plant Expansion involved new wastewater process structures, including a screening building, bioreactors, secondary clarifiers, aeration and thickening building, RAS pump station, gravity thickeners, service tunnels and miscellaneous chambers.

The project also called for the construction of a new maintenance building and pre-engineered storage building.

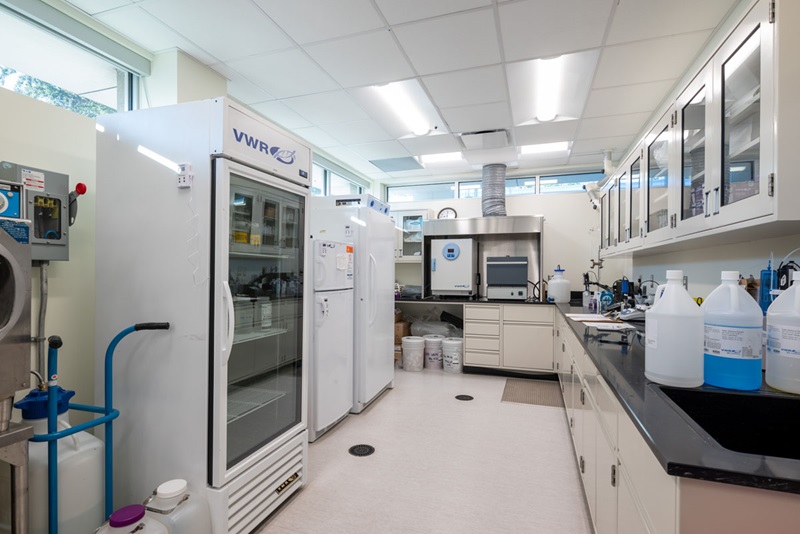

At the existing plant, modifications, expansion and upgrades to existing structures included a new digester electrical room, new headworks, a new sludge dewatering building, a new digester, and the operator services building and operations building.

Site-works included ground improvements for structural foundations, rock blasting and removal, excavating, backfilling, grading, drainage, fencing, site dewatering and landscaping.

Roadworks included a new gravel roadway, curbing and asphalt paving.

The site utilities included new storm sewers, sanitary sewers, water service, reclaimed service system water, natural gas and underground electrical.

Further to this, the project included the installation of yard process mechanical piping for interconnection of the proposed works; process equipment supply and installation including fine screens, screenings washer/compactor, grit washer classifiers, conveyors, aeration blowers and diffusers, secondary clarifiers, dissolved air flotation tanks, cen-trifuges, polymer systems, pumps, mixers, digester gas mixing system, gates and other specified equipment.

The contract included the supply and installation of foul air treatment systems including primary odour control facility, FRP ducting, fans, valving and carbon scrubbers; the installation of mechanical piping, valves, fittings and appurtenances to interconnect equipment and tie-into proposed works; the demolition of existing structures, equipment, piping and electrical devices, and tie-ins to existing structures and maintenance of existing plant operations. A new electrical service, substation, transformers and standby diesel generator were also required.

Project Delivery Methods:

Project Sectors:

Project Services:

Project Owner:

- Regional District of Nanaimo

Project Consultant:

- AECOM Canada Ltd.

Year of Completion:

2020

Related Projects

-

Denis St. Pierre Water Pollution Control Plant Expansion

Lakeshore,

Ontario -

Tofino Wastewater Treatment Plant

Tofino,

British Columbia -

Arnprior Water Pollution Control Center Expansion

Arnprior,

Ontario